3-dimensional printing engineering has advanced substantially in recent times, reworking industries and enabling creativeness in fields that range between engineering to fashion. Originally a distinct segment tool used by scientists and engineers, 3D printing has now come to be available to hobbyists, designers, and also educators. The elemental plan behind 3D printing is fairly uncomplicated: objects are produced by depositing material layer by layer right up until the desired shape is reached. This additive producing method, compared with traditional subtractive producing solutions that involve cutting far from a strong block of material, decreases squander and permits the creation of complicated structures Which may be unattainable to make working with standard procedures.

One of many critical parts in the 3D printing system is definitely the printer itself, that has a couple of distinct kinds that provide distinct uses and run working with diverse materials. By way of example, Fused Deposition Modeling (FDM) printers, one of the most common kinds out there, use thermoplastic filaments that happen to be heated and extruded by way of a nozzle to make up the item layer by layer. These printers are well-liked amongst newbies and experts alike due to their affordability and versatility. Another form is Stereolithography (SLA), which utilizes a laser to treatment liquid resin into reliable type. SLA printers are recognized for their high precision, building them ideal for making in depth models. Furthermore, Selective Laser Sintering (SLS) printers use a laser to fuse powdered components like nylon or steel, allowing for to the production of sturdy, sturdy parts. Each and every of these varieties has its advantages and is chosen dependant on the requirements from the task at hand, regardless of whether it be precision, energy, or Price.

Content preference is another important Consider 3D printing, as the Houses of the fabric effect the final object's characteristics. Polylactic Acid (PLA) and Acrylonitrile Butadiene Styrene (ABS) are two of the preferred thermoplastics Utilized in FDM printing. PLA, derived from renewable methods, is biodegradable and simple to work with, making it excellent for novices. ABS, Conversely, is recognized for its toughness and resistance to warmth, that makes it appropriate for purposeful prototypes and elements. Other components, including PETG, give you a balance of versatility and energy, though TPU, a flexible filament, permits the creation of sentimental, elastic elements. Resin-based mostly printers, for instance SLA designs, normally use photopolymer resins that harden less than UV gentle. These resins are available a variety of styles, including typical, challenging, adaptable, and even dental-grade, enabling significant precision for applications like jewellery design and style, dental molds, and intricate models.

The 3D modeling system is the inspiration of any printed item, as just about every layout should to start with exist inside of a electronic format. Modeling software program, for instance Blender, Fusion 360, and TinkerCAD, enables buyers to generate or modify electronic representations of their ideal objects. Some software program applications tend to be more obtainable to newbies, while others cater to State-of-the-art consumers with intricate prerequisites. After the model is prepared, it is transformed right into a format named STL or OBJ, which breaks down the design right into a mesh of triangles the printer can interpret. This file is then fed into slicing program, which translates the design into a number of Recommendations that guideline the printer regarding how to lay down Each individual layer. The slicer is important for altering parameters like layer peak, infill density, and print speed, which impact the print’s high-quality, toughness, and time necessary for completion.

Certainly one of the benefits of 3D printing is its software in rapid prototyping. In past times, making prototypes included comprehensive time and price mainly because of the have to have for molds or customized tooling. With 3D printing, corporations can produce a number of iterations of an item within just days, if not several hours, enabling for more quickly responses and adjustments. This flexibility has verified priceless in industries including aerospace, automotive, and healthcare, in which quick screening of components is vital. Engineers and designers can speedily transfer from notion to Bodily prototype, which allows for testing of variety, match, and performance without a significant financial investment in output methods.

In recent times, 3D printing has expanded into bioengineering, giving new possibilities in the professional medical area. Just about the most groundbreaking purposes is bioprinting, where residing cells are used to make tissue structures. Though nonetheless in experimental phases, bioprinting has the prospective to provide tissues and organs which could someday switch ruined components within the human entire body. This software of 3D printing has elevated moral queries and regulatory issues, but its potential to revolutionize medication is undeniable. Further than bioprinting, professional medical gurus have also adopted 3D printing for custom prosthetics and implants, which may be tailored to an individual’s certain anatomy. This customization enhances convenience and features for clients, resulting in superior recovery results.

The customization element of 3D printing has also observed an area in The style and style industries, where creators use it to establish exclusive garments, jewellery, and equipment. Designers can experiment with styles and resources that might be tricky to achieve via classic techniques. One example is, 3D-printed textiles have been designed working with flexible materials that mimic cloth-like Qualities, making it possible for designers to force the boundaries of wearable art. This technologies also enables sustainable tactics in fashion, as designers can generate objects on desire, lowering the waste connected with mass production.

Instructional institutions have embraced 3D printing for a worthwhile Resource for instructing STEM (science, technologies, engineering, and arithmetic) concepts. By allowing for college students to develop Actual physical models of sophisticated ideas, 3D printing can greatly enhance comprehension and engagement. For example, students researching biology can print models of molecules, cells, or organs, which can provide a more interactive Studying knowledge than textbooks or video clips by yourself. In engineering systems, learners can experiment with developing and printing parts, Finding out about concepts such as structural integrity and substance Houses. This hands-on approach has tested to generally be helpful in cultivating dilemma-resolving skills and creative imagination amongst students.

When 3D printing technologies continues to advance, usually there are some problems that stay. Among the list of most important is print high-quality. Even with improvements, 3D-printed parts can even now have problems with issues like warping, layer shifting, or inadequate adhesion involving layers. These complications could be minimized through mindful calibration and good settings 3d printing software in the slicing computer software, but they tend to be unavoidable for newbies. An additional problem is print speed. 3D printing is usually a sluggish method, with complex types getting hrs or maybe days to finish. Improvements in hardware, like multi-nozzle units and large-pace printers, goal to handle these limitations, but substantial development is still needed to make 3D printing faster and a lot more trustworthy for mass creation.

The environmental affect of 3D printing is a topic of ongoing analysis and debate. About the 1 hand, additive production is much more resource-economical than traditional subtractive solutions, because it makes a lot less waste. However, the environmental footprint of the elements used, specially plastics, can not be dismissed. Although some firms are creating biodegradable filaments and recycling plans, most 3D printing components are usually not conveniently recyclable and may contribute to air pollution Otherwise disposed of correctly. Innovations in sustainable supplies, including recycled filaments and bio-based resins, are promising ways towards decreasing the ecological impact of 3D printing, but widespread adoption of these products are going to be important to make a substantial distinction.

Regardless of these issues, 3D printing engineering demonstrates huge possible for the future. One particular space of Lively investigate is multi-material printing, wherever printers are Geared up to manage unique resources in only one print. This ability would empower the development of objects with diversified textures, strengths, and colors, opening up prospects For additional sophisticated and purposeful patterns. Yet another promising area is in substantial-scale construction, where by concrete-based mostly 3D printers can build entire structures. Though nonetheless in its early levels, 3D printing in construction could lead on to more inexpensive and faster housing options, specifically in regions influenced by organic disasters or housing shortages.

In summary, 3D printing has recognized by itself like a groundbreaking technologies with applications throughout various fields. From building intricate designs and prototypes to advancing healthcare solutions and exploring sustainable producing, 3D printing continues to drive the boundaries of what is feasible. The versatility of the engineering lies in its capacity to carry electronic types to life, delivering an unparalleled level of creative imagination and customization. As investigation and progress progress, the way forward for 3D printing promises more remarkable programs and enhancements, reshaping industries and possibly even everyday life.

Joshua Jackson Then & Now!

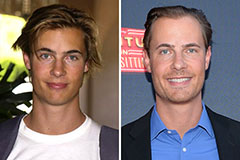

Joshua Jackson Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Matilda Ledger Then & Now!

Matilda Ledger Then & Now! Terry Farrell Then & Now!

Terry Farrell Then & Now! Kerri Strug Then & Now!

Kerri Strug Then & Now!